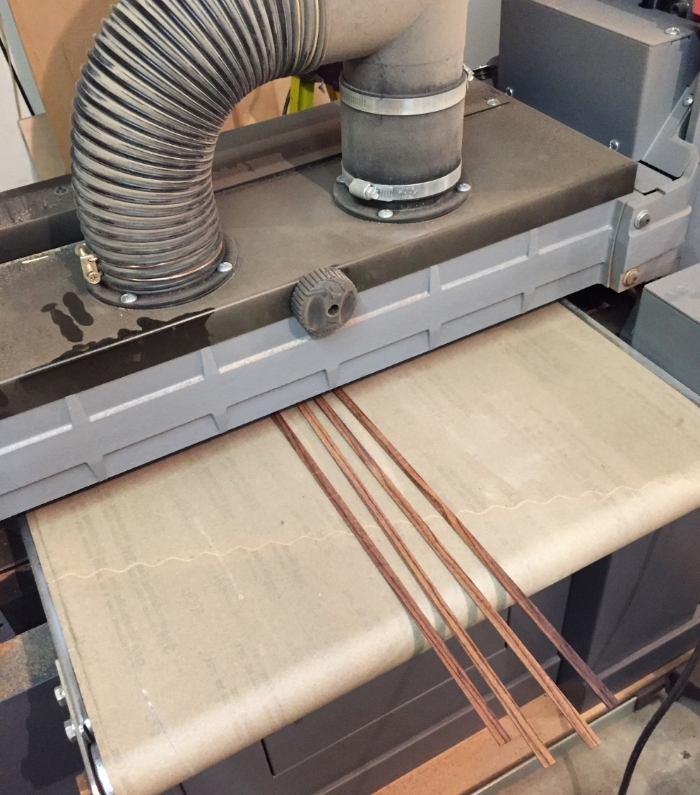

Whether bindings are purchased or cut in the shop from larger stock, they have to be accurately dimensioned for the particular instrument. Getting them to the right thickness is easy. Just run them through the thickness sander:

Getting them to the right height is a little more work. In addition to the correct height, the edges need to be square with the flat side. I've been using a funky method that took too much time and finally got tired of it so a new fixture was in order.

This clamps the binding strips between two straightedges that are 1/8" thick. The one on the right is fixed and the other slides laterally over a range of 1/2". The binding strips are placed in the slot between the two straightedges and the left one is slid firmly against them so they can't wobble from side to side. The sliding side is held in place with hex head screws.

The whole assembly is then run under the thickness sander. There are always any number of ways to skin cat but this works well for me.