HERE'S AN OLDIE BUT GOODIE:

A review of a six-string Makore baritone was published a couple of years ago by Hodge (“Doc-J”), one of the stalwarts on the Ukulele Underground forum. Here’s the link to the full thread:

And here’s the link to the description of this instrument on The Ukulele Site:

https://theukulelesite.com/shop-by/ono-custom-bear-claw-spruce-makore-6-string-baritone.html

THE PROOF IS IN THE PUDDING...

…so in November, I took two tenors and a concert to the annual exhibition of the Ukulele Guild of Hawaii and left them with Andrew at The Ukulele Site. Andrew takes much better pictures than I ever will so here are the listings:

https://www.theukulelesite.com/ono-custom-spruce-walnut-18-scale-tenor.html

https://www.theukulelesite.com/ono-custom-spruce-ziricote-tenor.html

https://www.theukulelesite.com/shop-by/ono-custom-spruce-koa-16-scale-concert.html

In addition to the construction technique, these also introduce a new body shape for all three sizes. The lower bout has been made a bit wider and rounder to maximize the working area of the top.

Andrew also produced a video that discuses the new instruments and features the fabulous playing of Corey Fujimoto and Kalei Gamiao:

HOW IS LAMINATION DONE?

It’s really not all that complicated. The three layers for the sides of this baritone were pre-bent using the standard hot pipe technique. After glue is thinly applied with a roller, the layers are clamped in the mold using a flexible caul and a lot of C-clamps. The back is “clamped” into a concave mold with vacuum pressure.

LAMINATED BACKS AND SIDES

For the past year or so, I’ve been working out techniques to laminate sides and backs. While I’m still able to use the conventional building method, this has become my standard because it has proven to produce a tonal profile that I and others find pleasing. The point isn’t to streamline the construction process and it certainly doesn’t do that. The goal is tonal with the secondary advantage of durability. This is not the sort of lamination that we see at the lower end of the market. Rather, it’s a more refined approach that has long been used by builders of premium acoustic guitars, both classical and steel string. I’ve completed five tenors, two baritones and two concerts and feel that the technique is now ready for prime time.

Lamination is a big subject but the brief overview is that by isolating the top so that vibration is not wasted by bleeding off to the sides and back, we can maximize volume, sustain and projection. These are tonal attributes that many players would find to be a positive. That's not to say that it's objectively "better" or that other builders don't get fine results from other ways of doing things. And we always have to remember that there is the ineffable quality of timbre. You like the sound or you don't and no builder or technique or combination of materials has or ever will achieve a sound that everyone agrees is the true and only holy grail.

There is a great deal of mythology about the properties of woods that are used for backs and sides. Much of what we hear in the ukulele world is cut and pasted from the guitar world, in which all sorts of opinions get floated. As interesting and entertaining as these might be, it’s by no means certain that something that is true for guitars is equally true for much smaller ukuleles. There is no doubt that the most sought after species such as rosewoods can make excellent instruments but ranking woods in any meaningful and objectively verifiable way isn't possible. What’s more, it can’t be said with any degree of reliability that the woods used for backs and sides have much effect at all upon the tone of the instrument. One hears lots of opinions but they are just that. What I have found is that the things that really matter are the top, the top bracing, other construction practices and the strings. It doesn’t seem to matter what woods are used for laminating backs and sides, as long as they are suitable tone woods, of course. I argue that the most useful tonal contribution made by the sides is to isolate the top by virtue of their mass not their species.

That’s not to say that the less common and more costly hardwoods have no value over the more common and less costly. They clearly have value as part of the aesthetic design of the instrument and I’m very much a proponent of the point of view that instruments should please the eye as well as the ear.

There’s no reason to believe that laminated backs make the same unusual tonal contribution as do laminated sides. A laminated back does have the advantage of improved structural integrity and resistance to dimensional changes with variations in humidity. I’ve tried to give my laminated backs the same tonal properties as my conventionally built backs by experimenting with the thickness of the laminates. As a practical matter, it seems that the backs are best when somewhat thinner than the sides and when a light wood such as spruce is used for the inner layer. I’ve also found that a middle layer isn’t necessarily required, though it might be appropriate in some situations.

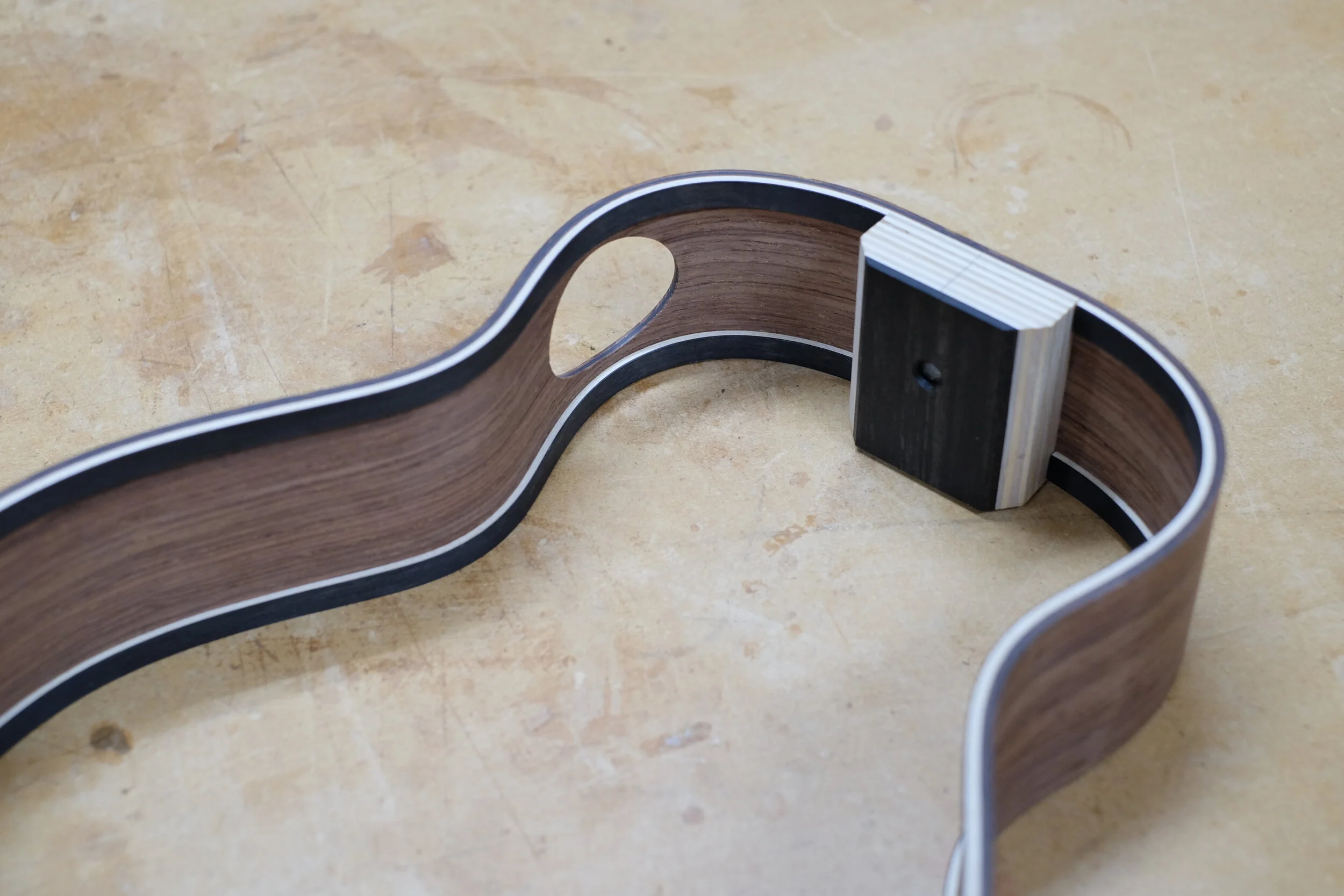

Here are the assembled sides of a tenor that is underway. The inner and outer surfaces are Amazon rosewood and the core is dyed anigre. The back is similar except the core is Adirondack spruce laid cross-grain. The laminated linings are maple and ebony.